Having said that many of the more expensive laboratory hotplates come with built in controllers, but I do not know if they accommodate ramp & soak. If youre using something like a hot plate or toaster oven for reflow. From there it kept on going to 300+ C before I aborted the test, so 'medium' was clearly too hot. If you believe it is not feasible for external control of the hotplate please let me know. It is part of our Surface-mount soldering may be easier than you think series. With nothing on it, and the dial set to 'medium', the hot plate temperature increased by about 100 degrees Celsius per minute, reaching the 183 C melting point of solder after roughly 90 seconds. Melting temperature must be exceeded by approximately 20. An issue might be whether the hotplate is able to cope with a PID controller that speeds up the profile to a significant degree, which would be the case in this instance.What do you think? Solder reflow is accomplished in the reflow zone, where the solder paste is elevated to a temperature greater than the melting solder point. My only thoughts on the subject is that a ramp & soak PID controller might be the answer. (Original design was 300W, but that was nowhere near enough.) I just drop the board onto the plate once it's up to temp, and remove after 20-30 seconds once the solder paste has melted. I'm thinking the Arduino might not be the way to go for the hotplate. Mine uses two 750W cartidge heaters from ebay with a PID/SSR controller/heatsink kit. I would appreciate your help and/or to point me to an existing instructable, or similar. The hotplate is problematic in that, on its own, it takes a relatively long time to reach target profile temperatures (and something like 20 mins to reach 225C). Its a good idea to measure your hot plate to determine what setting generates this heat. The hotplate is problematic in that, on its own, it takes a relatively long time to reach target profile temperatures (and something like 20 mins to reach 225C). This is around 180-190C depending on your solder.

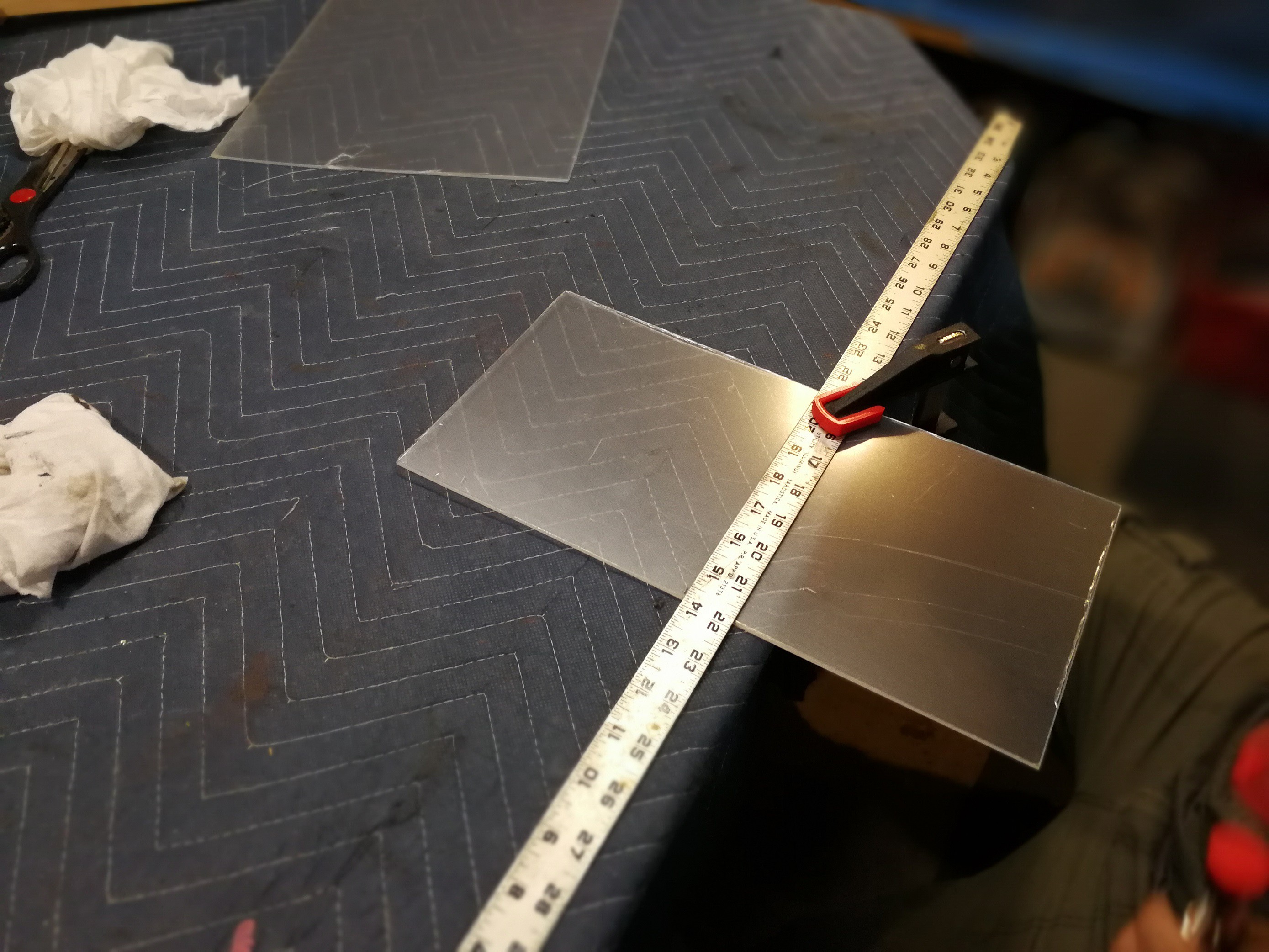

One area that I am not sure about is that my oven incorporates & requires a timer for reflow soldering to work but the hotplate does not have a timer. One area that I am not sure about is that my oven incorporates & requires a timer for reflow soldering to work but the hotplate does not have a timer. I'm thinking of using it for smaller jobs, not complete pcb reflows. The board, which was a single snaking trace on the top of an aluminum substrate, did heat up as it was supposed to. I have an existing setup for reflow soldering using an oven, Arduino, thermo amplifier & thermo couple.Ĭan I use the same setup with my hotplate (laboratory quality) or do I have to introduce other hardware to the equation. Carl’s first attempt at making a hot plate yielded lukewarm results.

0 kommentar(er)

0 kommentar(er)